Electrical hazards from high-voltage drive systems or high-voltage batteries in electric and hybrid cars

In this context, the turnaround in transport is of course also a major issue, especially the topic of electromobility. In this blog post, we will discuss the potential dangers of the high-voltage technology used in modern electric vehicles and which groups of people and industries will be affected by this future development.

Sources of danger with high-voltage technology in drive systems of electric vehicles and affected persons and industries

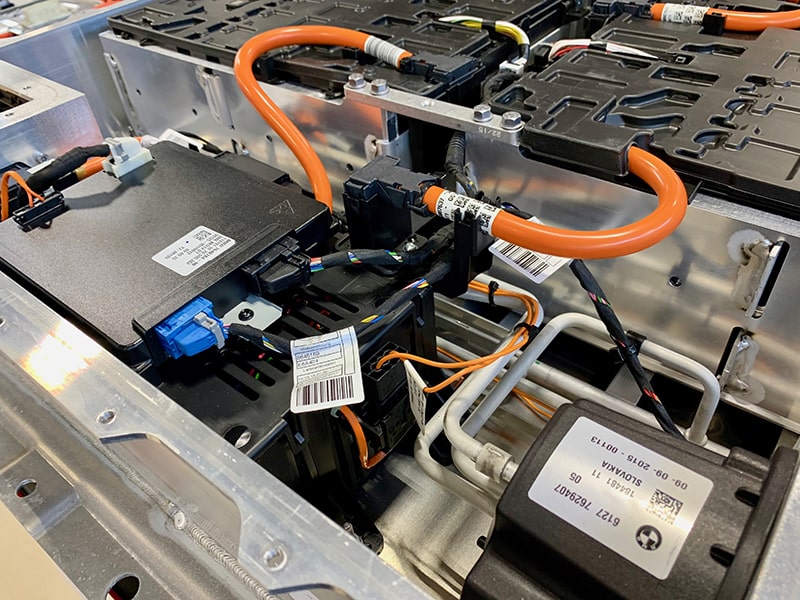

Vehicles with high-voltage technology are usually electric vehicles or hybrid cars that operate the drive and auxiliary units with alternating current > 30 V and ≤ 1000 V or direct current > 60 V and ≤ 1500 V. This has consequences for a number of industries and groups of people who have not previously come into contact with such high-voltage technology to this extent.

The currents in electric vehicles reach up to 500 A. This results in enormous electrical power. In addition, there are high current peaks when starting and braking, and the rapid switching processes generate broadband interference spectra that lead to the emission of interference over a wide frequency range. High magnetic field strengths also occur during charging and close to the drive train.

The required high-voltage batteries, usually lithium-ion batteries, also operate at much higher voltages and have a much greater energy potential than conventional car batteries. As a result, special requirements are placed on internal and external transport and storage.

Breakdown and accident assistance for electric vehicles with high-voltage technology

How do you actually recognize hybrid or electric vehicles? There are essentially three common characteristics:

- Writing on the dashboard or on the vehicle

- Orange high voltage cables

- Marking on the high-voltage components

Electric vehicles with high-voltage systems are intrinsically safe. Intrinsic safety means that the user is guaranteed complete protection against contact and arcing in relation to the high-voltage electrical system by means of suitable technical measures. Even in the event of a breakdown, drivers can assume that they are not exposed to any electrical hazards.

This also applies to a large extent to breakdown service, as long as no intervention in the high-voltage systems is necessary to rectify the fault and the vehicle does not have to be damaged in an accident or recovered from snow or water. The requirements for breakdown assistance and towing are reasonably manageable. More dangerous and therefore more demanding in terms of safety precautions are accidents and rescue operations.

Breakdown service / towing

Breakdown service personnel must receive instruction in the design and operation of electric or hybrid vehicles with high-voltage systems. Here the conditions for non-electrical work of the DGUV Information 200-005 apply.

In general, the following applies:

- Keep your hands away from high-voltage components and orange coloured cables!

- Remove the ignition key and then pull out the isolating plug/disconnector of the high-voltage battery.

- Visual check whether high-voltage components are damaged

- Work on the high-voltage components may only be carried out by persons who are qualified to work on vehicles with high-voltage systems

- Even after switching off the high-voltage system, a residual voltage may still be present – for several minutes, depending on the manufacturer. In this case it is essential to observe the marking.

In the case of towing, the following applies: Loading an undamaged vehicle onto a recovery vehicle (plateau vehicle) is harmless. When towing with rope or rod, the manufacturer’s instructions must be observed.

Qualification of specialists for high-voltage technology

For electrotechnical work on high-voltage systems, it is necessary to provide employees with the theoretical electrotechnical basics and to familiarise them with the practical skills in handling the respective high-voltage components, tools and aids.

The qualification (i.e. the contents and the time frame) is defined in three levels depending on the work to be carried out. The listed qualification contents are exemplary and must be adapted to the concrete requirements of the activities. The qualification shall be concluded with a proof of the acquired skills and knowledge by a theoretical and practical examination. The proof of performance must also be documented.

The first and foremost duty to prevent accidents in the company is always the employer’s responsibility. The employer must ensure that electrical systems and equipment are only installed, modified and maintained by a qualified electrician or under the direction and supervision of a qualified electrician in accordance with the electrical engineering rules.